In this industry sector, the IMACO filling systems use mass or magnetic flowmeters Krohne, Endress + Hausser. Parts that are in direct contact with the product are made of PTFE, PVC, titanium and ceramic. The filling space is ready for connection to the central ventilation.

Closing machines can be equipped with various types of rotary sorters and closing units for the application of screw or press-on caps.

Labeling machines use infeed chain orientator and upper hold down device which together with high-quality labeling heads allow for precise and perfect application of labels (front, back, and wrap-around) to the packaging.

The machine frame is made from stainless steel. Depending on the aggressiveness of the filled product, it can be protected with a special coating or plastic covers.

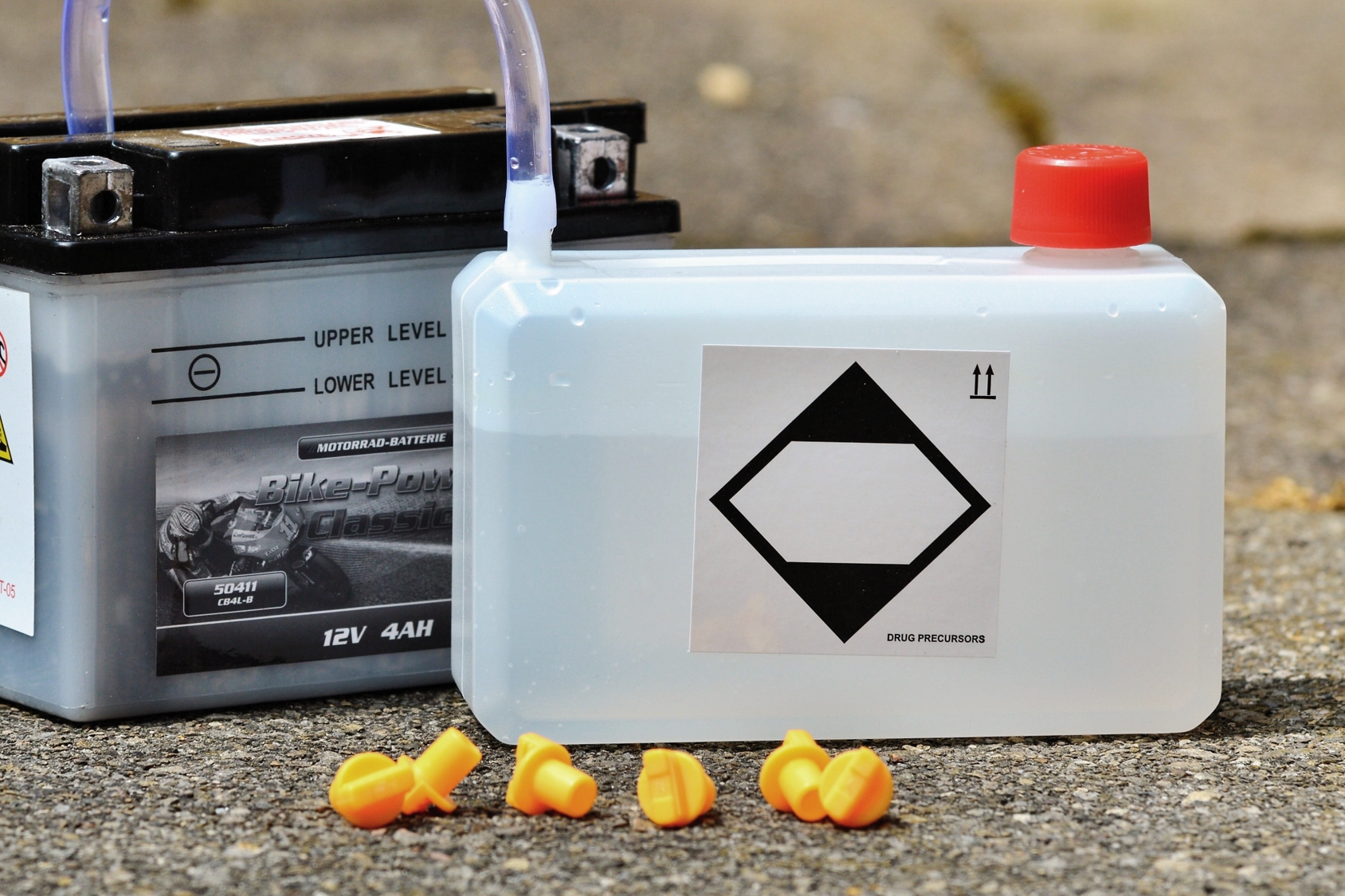

In this industrial sector, the IMACO Group is able to fill products such as:

- acids

- lyes

- organic solvents